Ergonomic Handrail

a handrail that conforms to the natural vertical movement of people

CMU School of Architecture

The movement of a person up and down a staircase is relative to each person, some skip steps, some walk at the steady pace, some bounce up and down. So how do you make a handrail that is purposefully designed around the entire movement of the body, rather than just the grasp of the hand? Moreover, how can this be done through contemporary fabrication techniques?

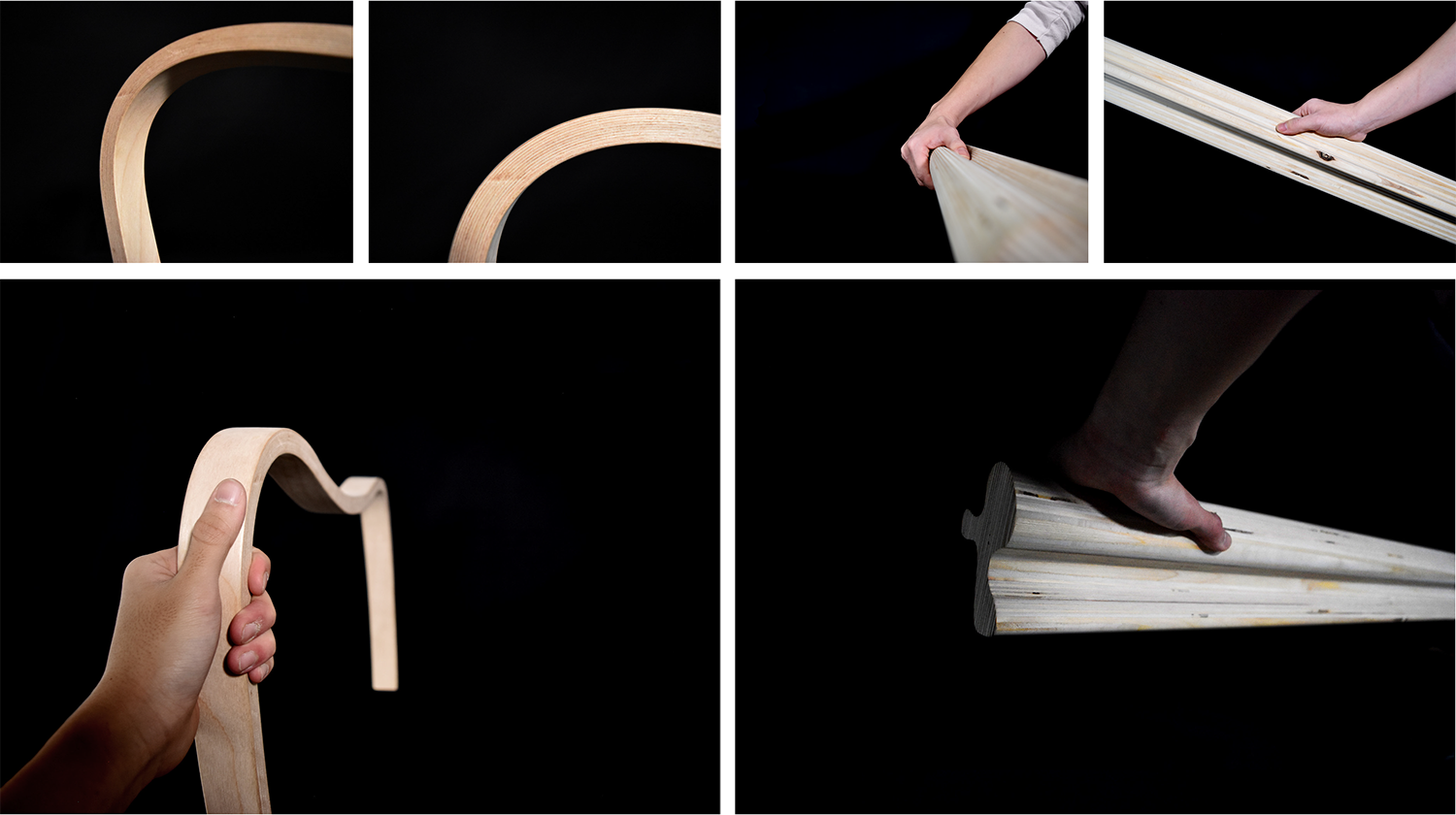

Taking the qualities of Alvar Aalto’s furniture and detailing, various forms were prototyped digitally and physically. There was special consideration for how a hand wrapped around the railing, much like many of Aalto’s handrails.

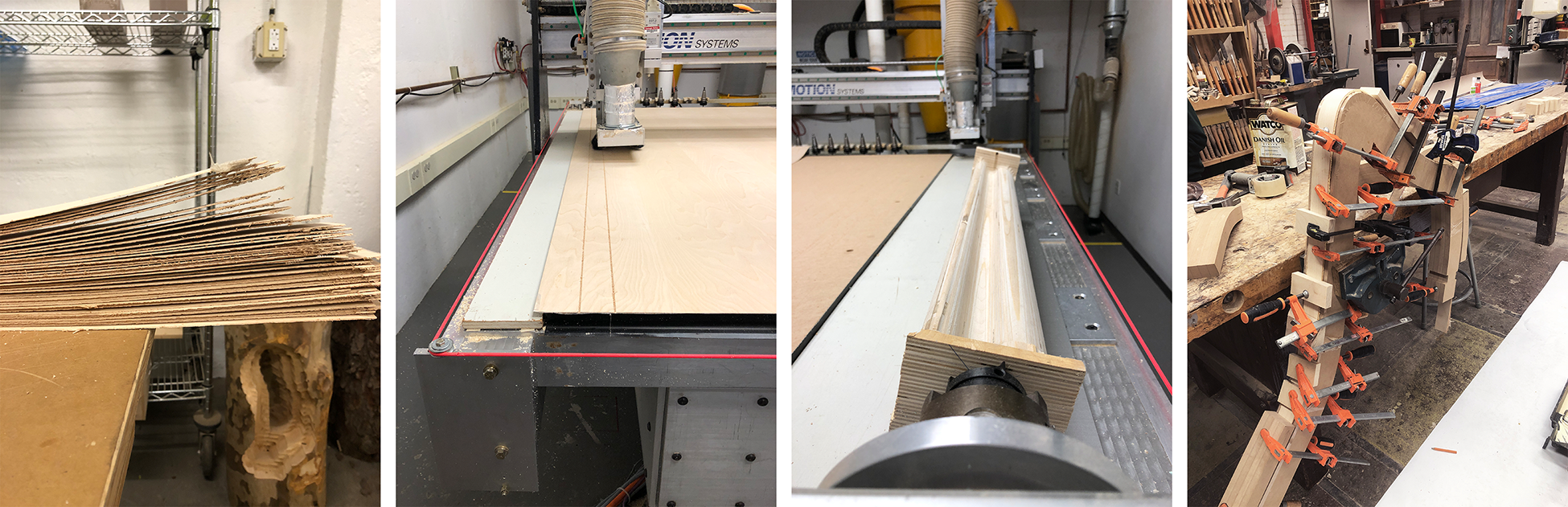

Through the full utilization of the CNC Machine at Carnegie Mellon University School of Architecture’s Design Fabrication Lab, as well as bent lamination techniques, this prototype of a handrail and baluster was created.

The Handrail

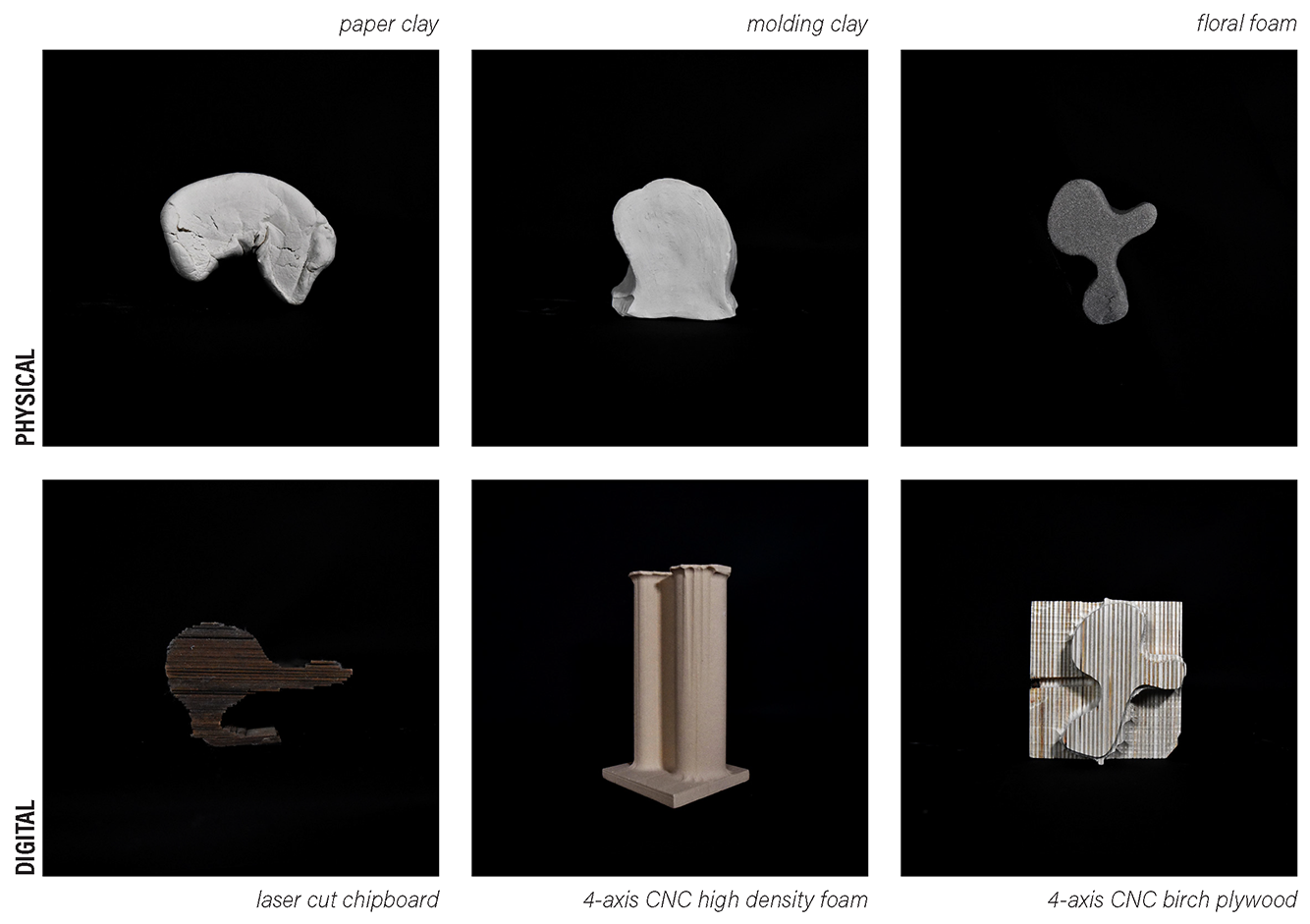

The initial prototyping involved analog processes of molding clay to fit a hand. The first clay prototype failed due to the density and crackling nature of paper clay. The second clay prototype used proper molding clay that was far easier to manipulate. However, it was apparent that the clay was too variant through its profile. The final physical prototype involved hand-carving floral foam over several days, fine-tuning it to various hand sizes and shapes.

Using this profile with sight modifications throughout each process, various forms were created through digital means (laser cutter, CNC). The chipboard was unsuccessful in the y-axis scaling, and the HD foam shifted during the CNC, resulting in scalloping.

The Baluster

Prototyping the baluster involved a far more digital to physical conversation. The form was first digitally iterated in Rhino until a satisfactory form was generated. This form was then profiled out on the CNC mill (2.5 axis) as a mold. For the first bent lamination tests, chipboard strips and standard multipurpose (Elmer’s) glue was used in a stagger method.

Through this mold, it was apparent that the extreme curve at the top would not be structurally sound; moreover, it would be difficult to wrap layers and layers of wood around the curve. The curve then was modified to a lesser degree and another mold form was milled out, this time with an outer mold to spread out the pressure of the clamps. After a couple of small layer tests, the final baluster was produced. The Aalto inspired handrail ended up taking the form of an object you want to hold on to, but also a form that invites you to let go.